Welcome to Jumper Magnetics

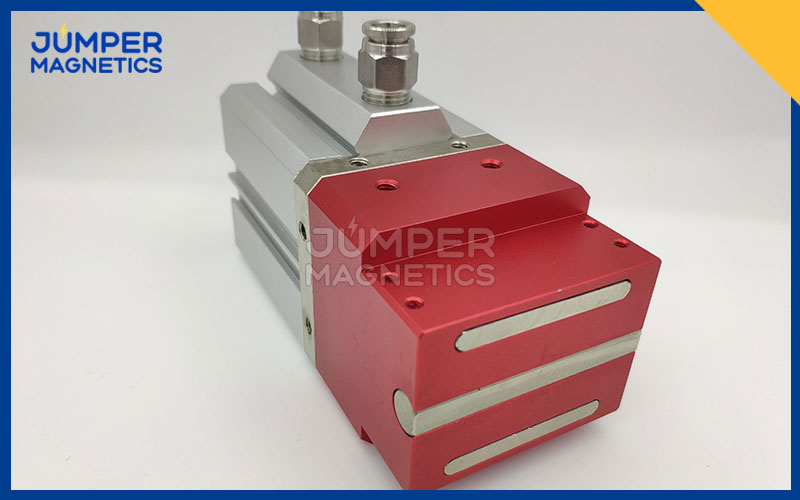

Pneumatic Magnets PPMG-Max100

PPMG-MAX100 Pneumatic switchable bi-stable magnetic systems are designed for robot arm in ferrous parts lifting. It use powerful permanent magnet inside as power source and pneumatic controlled to switch the MAG and DEMAG phase.

PPMG-MAX100 magnetic gripper is much more secure than traditional electric magnets because its holding force exist even when vacuum or electric fails. That’s why it could be widely used in robot gripping and automation applications.

PPMG-MAX100 Pneumatically Magnets could also handling perforated material, ie metal sheets with holes. This is a huge advantage compared to vacuum handling solutions. BTW, the Pneumatic Switchable Permanent Magnet is maintenance free and could ensure a long service time.

With the help of threaded holes in the sides and top of the magnet enables use of pole extensions and multi way for installations. Thus to be used for both flat and round or irregular metal lifting.

The Pneumatic magnets cylinder with piston control for sensor recognition of piston position of the magnetic gripper, could provide signal feedback to the whole control system of the automation line/robots